Roof flashing is a guardian against leaks, strategically placed to redirect water away from areas where roof structures meet with a chimney, wall, or other vertical surface. Think of roof flashing as a splash guard keeping water from entering between the roof and other surfaces.

Table of contents

What Are the Different Types of Roof Flashing and Their Roles?

Considering the extensive range of roof structures and designs, it’s no surprise that there are numerous flashing types tailored to serve specific functions. Let’s delve into the different types of roof flashing and their unique purposes. We’ve showcased each flashing type with a simple image highlighting each flashing type.

Continuous (Apron) Flashing

Imagine an apron guarding against spills; this long, single metal strip works similarly for roofs. Its main task is to direct water to the underlying shingles. While large continuous flashing segments may wrestle with a home’s seasonal shifts, well-placed expansion joints allow them to adjust seamlessly, warding off leaks.

Base Flashing

Key roof elements, like chimneys, often require a dual-flash setup. This two-layer approach ensures rain encounters a guiding barrier. Adapting to weather-induced shifts in roofing materials, base flashing, lays the groundwork.

Counter-flashing

Working hand-in-hand with base flashing, counter-flashing positions itself above, creating a stalwart leak-prevention duo.

Step Flashing

Picture a metal rectangle, folded at 90 degrees. This describes step flashing, essential where roofs meet walls. Its layered setup with shingles directs water away from wall junctions.

Skylight Flashing

While some skylights have built-in flashing, many require custom or separately purchased flashing for the best shield against elements.

Valley Flashing

To fortify roof intersections, or open valleys, metal flashing serves as protective armor.

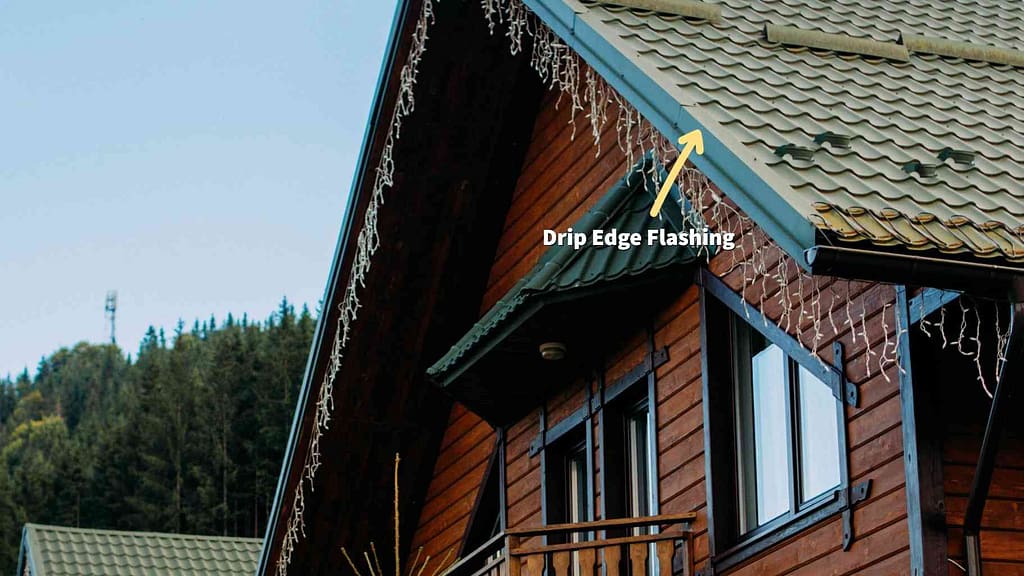

Drip Edges

This thin metal strip lines the roof edge, ensuring water drips away, thereby defending the infrastructure against moisture damage.

Which Flashing Material is Right for Your Roof?

From traditional lead to innovative composites, each material has its unique advantages and disadvantages. Read further to explore the diverse range of materials used in roof flashing to help you make an informed decision for your home.

Aluminum

Aluminum stands as a prominent choice for numerous flashing locations such as valleys, chimneys, and walls. In Austin, Texas, for example, aluminum and galvanized metal are the predominant materials used for flashing.

What sets aluminum apart is its versatility, given that it’s available in various formats like pre-formed shapes, sheets, and rolls. Aluminum can also be painted to match your home’s color. While its moderate price point coupled with durability makes it a favorite, it does come with a caveat. The uncoated version of aluminum tends to corrode upon direct contact with mortar and cement, necessitating the use of its coated counterpart in such scenarios.

Copper

Copper, albeit pricier than some alternatives, is renowned for its unmatched durability. It seamlessly fits into a range of applications, from valley flashing with tiles to chimney flashing and wall intersections. When installed correctly, the longevity it offers is commendable, lasting many years with minimal maintenance.

Stainless Steel

For environments that are exceptionally harsh (hail), stainless steel emerges as the champion because of its strength. Price-wise, it stands half the price as copper, making it a premium choice. A notable highlight is its compatibility with mortar and concrete, devoid of any corrosive reactions.

Lead

Tracing back its roots as one of the oldest materials in roof flashing, lead boasts a potential lifespan of up to 200 years. Its soft texture facilitates easy molding, but this doesn’t compromise its robustness. Lead effectively combats water intrusion and remains stable across fluctuating environmental conditions. Additionally, it doubles up to offer heat insulation and sound resistance.

Health Risks with Lead Flashing

However, those working directly with the material must be cautious. Direct exposure can pose health hazards. That’s why OSHA (Occupational Safety and Health Administration) requires that lead materials be managed with appropriate protective gear or by contractors equipped for the task. If not properly installed, lead can contaminate water runoff from rooftops potentially introducing pollutants into the plumbing system which may result in poisoning.

Plastic

For homeowners seeking a budget-friendly option, plastic flashing emerges as a viable pick. Plastic flashing, depending on its type, can be resistant to UV radiation and can have a good lifespan. However, some plastic flashings can become brittle or warp over time, especially when exposed to constant sunlight or extreme temperature fluctuations.

Composite

“Composite” refers to a combination of multiple materials. In the context of roofing, composite flashing can include materials such as asphalt, polymers, and fiberglass combined to create a durable flashing solution.

Known for its impressive strength and dimensional stability, composite remains unchanged in shape, irrespective of water absorption or release. Its durability has won the trust of many, making it a sought-after choice in contemporary roof flashing endeavors.

Choosing The Best Material for Coastal vs. Dry Areas

The choice of roof flashing material is crucial and should be determined based on the house’s location and the prevailing climate. Environmental factors, such as exposure to salt air and varying weather conditions like excessive heat or heavy snow, can influence the longevity and efficacy of the flashing.

For those residing in coastal regions like Florida, the constant exposure to saltwater, high winds, and the corrosive environment are significant considerations. Copper emerges as the top contender for roof flashing in these areas due to its impressive resistance to salt corrosion. Its durability ensures that the structure remains protected from the relentless salty air, thereby enhancing the overall longevity of the roof.

We’ve read articles claiming that stainless steel roof flashing is the best for homes closest to salty environments such as the ocean. But typically, those articles are sponsored by stainless steel flashing manufacturers. A true experienced roofer whose focus is ocean front properties will confirm.

In areas with dry climates, aluminum is frequently chosen for roof flashing because of its resilience to extreme temperatures and its low moisture absorption. This ensures longevity and lessens the need for maintenance. Yet, it’s important to note that if aluminum is to be used alongside concrete and masonry, a protective coating is essential. This is because untreated aluminum can react with alkaline surfaces, leading to its degradation.

Can I Replace Flashing Myself?

Roof flashing is an unsung hero in the world of home construction. However, it’s important to recognize that every house is unique in its design and structure. Professional roofers are acutely aware of this, which is why many choose to craft their own flashing directly from sheet metal. By molding and shaping the metal to align perfectly with a home’s specific contours and junctions, they ensure an optimal fit and, consequently, the best protection against potential water damage.

But this craftsmanship in roofing also brings to light the potential pitfalls of taking a DIY approach, especially for those not seasoned in the nuances of the trade. While the DIY spirit is commendable, and often even cost-effective, roofing requires a certain level of expertise. A common misstep is the selection of inappropriate or ill-fitting flashing.

For instance, some pre-made flashing types, such as head or cap flashing, are designed with a particular purpose in mind: to shield doors and windows from water. If these are mistakenly repurposed for roofing, the results can be far from ideal. They might not only under perform but can also break or falter, leading to leaks and subsequent structural damages that can be expensive to repair.

For homeowners considering a DIY route for their roof flashing, thorough research is paramount. It’s crucial to understand the unique structural needs of your home and to ensure that the materials you’re working with are truly fit for the purpose.

What’s The Estimated Expense For Flashing Replacement?

A professional roof assessment might reveal anything from a minor flashing hiccup to a need for comprehensive strip replacement. On a broad scale, flashing repair expenses generally lie between $16 and $30 for every linear foot. This estimate often envelops both the expenditure on the new flashing and the sealing caulk, which alone can set you back by a minimum of $10.

When breaking down the costs, most homeowners find that a typical flashing mend falls in the $300 to $600 bracket. On the other hand, a complete overhaul can touch anywhere from $400 up to $1,800. If your residence boasts a sizable chimney, especially those built with stone, brace yourself for an outlay potentially exceeding $2,500 for its flashing revamp.

However, several variables shape the final tally for a flashing substitution or refurbishment, apart from the manual labor:

- Chosen flashing material

- The square footage needing an update and the degree of existing damage

- Variations in chimney dimensions and their construction materials, if present

- The architectural design of the roof

- Comprehensive roof evaluation charges

- Post-work cleanup expenses

By taking all these elements into account, homeowners can achieve a clearer picture of their potential roofing investments.

Summary

Your roof isn’t just about shingles and flashing. It’s a complex system of components that work in harmony to shield your home. Knowledge about each component, like flashing, not only aids in maintaining your home’s integrity but also in making informed financial decisions about its upkeep. Always ensure you’re aware of what you’re investing in during a roof replacement, because every piece plays a pivotal role in your home’s protection.

If you plan on keeping your home for the rest of your life. Consider more durable materials. If you plan on moving in the next 5 years, save money and invest in low-cost materials. The choice is completely up to you.

Post fact checked by Joseph Castro – 8/15/23